EYE PROTECTION GUIDE

How important is safety eyewear?

Our eyes are the most sensitive of our senses. Good eyesight depends on the delicate interaction of a complex optical system.

Since the eye is so easily damaged it’s not surprising that many workplace accidents result in permanently impaired vision.In 2015 12,000 New Zealanders filed a claim with ACC for an eye injury suffered at work.

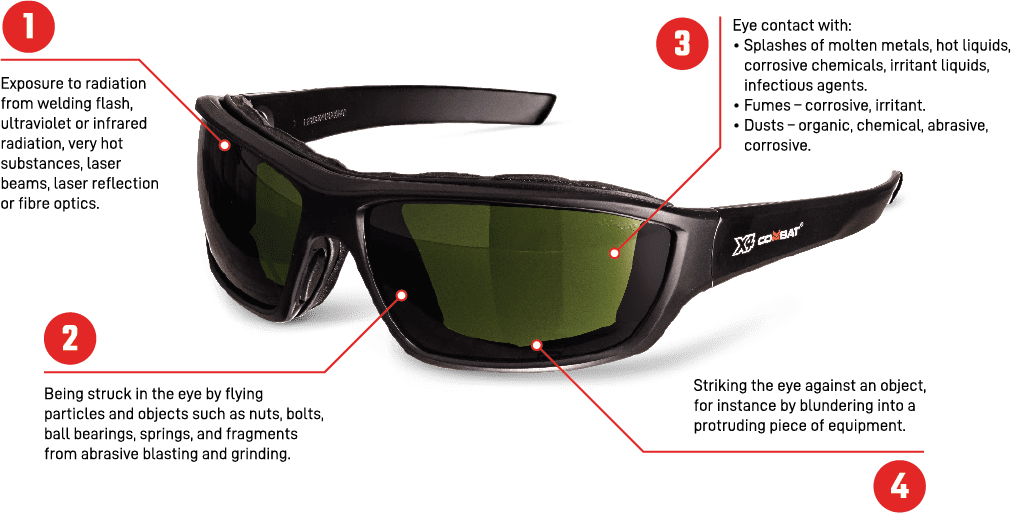

Over 90% of these workplace eye injuries were due to four main causes:

Assessing The Workplace risks

The Health and Safety in Employment Act 1992 requires employers to take all practicable steps to eliminate these hazards or to isolate the hazard from the employee.

Where elimination or isolation is not possible, employers must take all possible steps to minimise the likelihood of harm. Where there is a potential danger to any employee’s eyes, personalised safety eyewear should be provided. In most cases this should be for medium impact protection.

If you are an employer, you need an appropriate eye safety program to:

- Identify and control hazards to prevent eye injuries before they happen.

- Provide employees with appropriate eye protection. Select eyewear to protect against the specific hazards in your workplace—radiation, flying particles or objects, splashes, fumes or dust. Ensure safety glasses fit properly. Eye size, bridge size and temple length all vary. Safety glasses should be individually assigned and fitted.

- Make provision for correct storage of safety eyewear in a pouch or case and replace scratched, pitted or ill-fitting eye protection immediately.

- Instruct staff in safe working practices and ensure appropriate eye protection is worn when required

- Train staff in use of their eye protection.

IS THERE A MINIMUM STANDARD FOR SAFETY GLASSES IN THE ESKO RANGE?

All our eyewear is tested and certified to meet AS/NZS1337: Personal Eye Protection, to at least Medium Impact Protection level.

This Standard sets out the specific requirements for eyewear to protect the user from impact, UV and other hazards in the workplace. Look for these symbols which indicate the product has been passed by an approved testing agency:

WHAT FEATURES SHOULD BE LOOKED FOR IN QUALITY SAFETY GLASSES?

Check to see that the spectacles have Australian Standards approval. There will also be lens markings indicating suitability for specific applications:

LENS MARKING | S | I or F | V or B | A | C | D | G | M | H | O | 0 | 1 | 2 | 3 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

TYPE OF LENS | Low impact rated | Medium impact rated | High impact rated | Extra high impact rated | Splashproof (goggles) | Dustproof | Gastight | Molten metal and hot solids resistance | High temperature use | Outdoor untinted (can be used indoors or outdoors) | Outdoor use, untinted, luminous transmittance 80–100% | Outdoor use, tinted, luminous transmittance 43–80% | Outdoor use, tinted, luminous transmittance 18–43% | Outdoor use, tinted, luminous transmittance 8–18% | Welding lens shade 5, as per AS/NZS1338:2012 |

xxxxxxxxxx | xxxxxxxxxx |

OUTDOOR WORKERS NEED UV PROTECTION TOO

In New Zealand conditions, eye protection against ultraviolet (UV) radiation from the sun is particularly important.

UV radiation can lead to eye complaints ranging from mild irritation to macular degeneration, cataracts and cancer. All safety glasses from ESKO prevent at least 99% of harmful UV rays from reaching the eye and the Magnum and Destination ranges block 100%.

Be aware that UV radiation can pass round the edge of glasses, so choose eyewear that is close-fitting.

Tinted lenses do not necessarily block more UV light, check the product information for the degree of resistance to UV light.

The amount of outdoor UV exposure will be influenced by where you are working. UV radiation from the sun is also reflected off the ground surface. Bare ground will reflect about 15% of UV radiation, the sea about 25% and snow about 80%.

Also protect your eyes by wearing a hat—a hat with a wide brim can reduce UV radiation reaching the eyes by around 50%.

HOW TO SELECT THE MOST APPROPRIATE SAFETY EYEWEAR

Safety eyewear used to look heavy and impractical, but all that has changed.

The latest generation of safety eyewear is well designed, stylish and modern. So fortunately, there is now much less reluctance by employees to wear safety eyewear when it is required.

With proper safety eyewear most injuries are preventable. But to be effective the eyewear must be appropriate for the hazard. Use this guide to narrow down the best eyewear for your particular requirement:

1.) LENS COLOUR

Clear Lens

Clear lenses protect against general indoor/outdoor hazards and UV rays

Smoke Lens

Smoke lenses are good for sunlight and outdoors glare conditions.

Bronze Lens

Bronze lenses work similarly to amber, giving enhanced contrast in low light but they also cut down glare in brightly lit situations.

Amber Lens

Amber lenses enhance contrast—ideal for low-light environments.

Polarised Lens

Polarised lenses cut out horizontal reflections from water, snow or flat road surfaces, greatly reducing distracting glare.

Mirror Coating

Mirror coatings give excellent filtering in strong sunlight and outdoors glare conditions

Shade-5 Lens

Shade-5 lenses are ideal for working in proximity to welding or in very brightly lit conditions.

2.) IMPACT RESISTANCE

Eyes exposed to impact danger from flying particles, sparks, shavings, shards?

Low Impact Rated: Spectacles that can withstand impact from an object moving at 12 metres per second.

Suitable for manual chipping, riveting, hammering, handling wire, brick cutting.

Medium Impact Rated: Spectacles, eyeshields or lightweight visor systems that can withstand impact from an object moving up to 45 metres per second.

Suitable for tasks like machine disc cutting, scaling, grinding, and machining metals, certain wood working operations, stone dressing, horticulture and gardening including lawn mowing and using weed eaters/ line trimmers

High Impact Rated: Can withstand impact from an object moving up to 120 metres per second.

Suitable for tasks like using explosive power tools, high speed disc grinding, metal cutting.

Extra High Impact Rated: Can withstand impact from an object moving up to 190 metres per second.

Suitable for tasks like shot blasting, ballistics, military, electrical maintenance.

3.) UV RATING

Exposed to UV light in outdoors glare or laboratory radiation?

Choose UV-blocking lenses.

4.) FOAM SEAL

Working in dusty environments?

Select glasses with a foam gasket that seals comfortably against the face—or, in high risk environments, goggles.

5.) GOGGLE STYLE

Do you need protection against hazardous splashes, flying particles, extremely dusty environments?

For the highest level of protection choose goggles.

Product Code | Description | Lens Colour | Impact Resistance | UV Rating | Foam Seal | Anti-Fog Lens | Anti-Scratch Lens | Goggle Style? | Elastic Strap Option | Can be worn over prescription glasses? |

|---|---|---|---|---|---|---|---|---|---|---|

E8100 | Combat EVA Foam

Seal Clear Lens | Clear | Medium | 99.9% | ||||||

E8102 | Combat EVA Foam

Seal Smoke Lens | Smoke | Medium | 99.9% | ||||||

E8200 | Combat X4 Clear Lens | Clear | Medium | 99.9% | ||||||

E8202 | Combat X4 Smoke with

Silver Mirror Lens | Smoke/Mirror | Medium | 99.9% | ||||||

E8203 | Combat X4 Shade 5

Welding Lens | Shade 5 | Medium |

99.9% | ||||||

1700 | Magnum clear lens | Clear |

Medium |

100% | ||||||

1702 | Magnum Smoke Lens | Smoke | Medium | 100% | ||||||

1703 | Magnum Amber Lens | Amber | Medium | 100% | ||||||

E6000 | X2 Premium Clear Lens | Clear | Medium | 99.9% | ||||||

E6002 | X2 Premium Smoke Lens | Smoke | Medium | 99.9% | ||||||

E6003 | X2 Premium Indoor/Outdoor Mirror Lens | Mirror | Medium | 99.9% | ||||||

8001 | Velocity Clear Lens | Clear | Medium | 99.9% | ||||||

8002 | Velocity Smoke Lens | Smoke | Medium | 99.9% | ||||||

8003 | Velocity Amber Lens | Amber | Medium | 99.9% | ||||||

E1000 | Econospec Clear Lens | Clear | Medium | 99.9% | ||||||

E1002 | Econospec Smoke Lens | Smoke | Medium | 99.9% | ||||||

E1003 | Econospec Amber Lens | Amber | Medium | 99.9% | ||||||

GMAX | G-MAX Silicone Goggle | Clear | Medium | 99.9% | Standard | |||||

2000 |

ESKO 2000 Econogoggle | Clear | Medium | Standard | ||||||

3000 | Esko Vispec Overspec Clear Lens | Clear | Medium | 99.9% | ||||||

3002 | Esko Vispec Overspec

Smoke Lens | Smoke | Medium | 99.9% | ||||||

E7020 | Panther Green Flash Mirror | Mirror | Medium | 100% | ||||||

E7020P | Panther Polarised Smoke | Smoke/Polarised | Medium | 100% | ||||||

E4000 | Xspex Clear Lens | Clear | Medium | 99.9% | ||||||

E4002 | Xspex Smoke Lens | Smoke | Medium | 99.9% | ||||||

E4004 | Xspex Bronze Mirror Lens | Bronze | Medium | 99.9% |

MORE INFORMATION

Click on the link for further information:

Worksafe’s guide to eye injuries, treatment, prevention and choosing eye protection

RELEVANT STANDARDS

- AS/NZS 1336:2014 Eye and face protection guidelines

- AS/NZS 1337.1:2010 Personal eye protection. Part 1: Eye and face protectors for occupational applications

- AS/NZS 1338.1:2012 Filters for eye protectors. Part 1: Filters for protection against radiation generated in welding and allied operations

- AS/NZS 1338.2:2012 Filters for eye protectors. Part 2: Filters for protection against ultraviolet radiation

- AS/NZS 1338.3:2012 Filters for eye protectors. Part 3: Filters for protection against infra-red radiation